Plastic material has become a important element in our lives for a long time, from packing supplies to playground devices, and medical units to vehicle pieces. However, the producing of plastic-type products continues to be traditionally covered with strategies such as injections molding, blow molding, and thermoforming. But today, we are going to discover the skill of Plastics Rotomolding, which includes revolutionized plastic-type material producing with its exclusive qualities and revolutionary strategies.

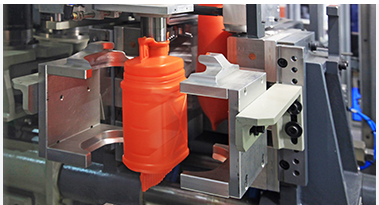

Rotomolding, often known as rotational molding, is really a relatively recent developing strategy that requires the heating of your hollow fungus on an axis, then adding the desired substance. The mildew is going to be rotated, creating the material to evenly layer the within the mold mainly because it cools down and solidifies. This procedure produces a smooth, hollow product, that may be created in a range of sizes and shapes, from small games to big tanks.

One of the important benefits of Rotomolding is its capability to use a wide range of materials, which includes PVC, nylon, and polyethylene. What this means is developers have the flexibility to produce custom goods with distinctive attributes, like UV opposition, chemical substance opposition, conditions amount of resistance, and flame-retardancy. Additionally, Rotomolding is well-suitable for generating prototypes or short creation works, that may decrease charges and quicken the development method.

Yet another major advantage of Rotomolding is its expense-efficiency. In contrast to shot molding or blow molding, which entail important upfront purchases in molds, Rotomolding only requires a single fungus, which is often used again for 1000s of periods. This results in reduce tooling costs, making Rotomolding a cost-efficient technique for producing large or intricate items.

As mentioned previously, Rotomolding is perfect for making huge and complex styles. Since the substance is distributed evenly all over the fungus, it makes it possible to create hollow objects that would be tough or extremely hard to manufacture making use of other strategies. The method also enables fuller wall surfaces compared to other techniques, that make goods more durable and immune to deterioration.

The distinctive components of Rotomolding make it particularly best for manufacturing a variety of products, such as water tanks, outdoor furniture, playground devices, health care gadgets, and gardening gear. As the demand for custom-made and durable goods grows, the usage of Rotomolding has become much more widespread in different sectors.

brief

In summary, the art of Rotomolding has revolutionized the way we think of plastic material developing, giving a variety of benefits and alternatives that traditional methods cannot match. It is an interesting and innovative strategy that features a significant long term in different industries’ manufacturing operations. So, it’s worth exploring the art of Rotomolding and exactly how it may advantage your business’s needs, regardless of whether it’s by means of quick prototyping or sizeable-size generation runs.