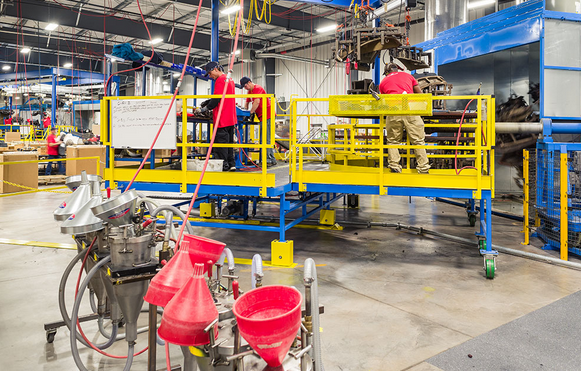

Rotomolding, also called rotational molding, is a producing process in which a hollow plastic-type material part is formed by warming the molding substance within a fungus that revolves around two perpendicular axes. This technique is commonly utilized to produce hollow plastic-type material goods with intricate forms, including toys and games, storage units, and storage space tanks. Just about the most essential aspects that figure out the success of the Rotational Molding method is picking the correct substance. Within this post, we’ll check out many of the most common materials employed in Rotomolding and explore important things to consider when selecting them.

Polyethylene (PE): Polyethylene is easily the most frequent materials in Rotomolding and gives several advantages, which includes exceptional effect amount of resistance, overall flexibility, and potential to deal with chemical substances and Ultra violet rays. PE offers great surface finish off and is available in various types, including substantial-occurrence polyethylene (HDPE), lower-occurrence polyethylene (LDPE), and linear lower-density polyethylene (LLDPE). HDPE is regarded as the typical type used and is favored for goods that might be in contact with unpleasant weather conditions and chemical substances.

Polypropylene (PP): Polypropylene is yet another popular choice for Rotomolding and has comparable qualities to polyethylene, including chemical amount of resistance, influence opposition, and adaptability. PP is often favored over PE for higher temp programs, since it has greater heat opposition. PP is another good choice for products which require greater stiffness and toughness.

Nylon material (PA): Nylon can be a thermoplastic substance that provides exceptional energy, sturdiness, and also heat opposition. Nylon material is commonly utilized for Rotomolding products that demand substantial durability and strength, like automotive components and devices parts. Nylon material comes in various kinds, including Nylon material 6 and Nylon material 6/6, every featuring its exclusive properties and benefits.

PVC: Polyvinyl chloride (PVC) can be a adaptable material popular in many plastic goods, including Rotomolding goods. PVC is a superb choice for goods that need good compound level of resistance, sturdiness, and low flammability. PVC can be found in many forms, such as adaptable and firm Pvc material, with different properties and positive aspects.

Polycarbonate (Laptop or computer): Polycarbonate is a obvious thermoplastic with outstanding clearness, affect resistance, as well as heat opposition. It can be commonly used in Rotomolding products including vehicle headlamps, light-weight includes, and crystal clear containers. Laptop or computer is usually more costly than other materials but provides special qualities making it a preferred option for certain programs.

Concerns when selecting Rotomolding components:

When choosing the right materials for Rotomolding, it’s important to look at a number of aspects, for example the merchandise functionality, required attributes, as well as the surroundings the item will be subjected to. Other variables which should be regarded as range from the charge, accessibility, and handling requirements. It’s also vital to look at the amount of article-generation work necessary, such as artwork or designing, to guarantee the picked substance can be simply embellished.

Simply speaking:

Selecting the most appropriate substance for Rotomolding is essential to guarantee the item fulfills the prerequisites in the program. Each material has exclusive qualities and positive aspects that ought to be regarded as to determine the finest suit for that item. The variety procedure must look into several aspects, for example the product operate, necessary qualities, and the atmosphere this product is going to be subjected to, so that the produced portion is reputable and efficient.