The plastic manufacturing has evolved with time, and new methods have been designed to create the approach more at ease and successful. One of these simple strategies may be the rotational molding approach (rotomolding), which has been used for quite some time. Rotomolding is actually a exclusive plastic-type material manufacturing procedure that produces complicated plastic-type parts by rotating a hollow mildew full of plastic-type material resins. The ingredients produced through this method works extremely well in a variety of manufacturing apps, through the vehicle Rotational Molding sector to the health-related industry. On this page, we shall explore what rotomolding is, how it operates, along with its advantages.

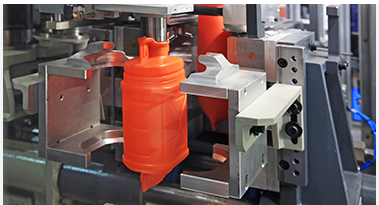

The rotomolding process starts off with the launching of your plastic-type material resin in to the mold. The mold is then shut down, as well as the mold is rotated in different directions allowing the resin to fully fill the fungus cavity. The mildew is then heated, along with the molten plastic-type forms a consistent coating on the inside of the fungus. As the mold consistently swivel, the plastic cools down and solidifies, making a hollow factor that conforms exactly towards the mold’s condition. The accomplished item is then taken off the mildew, and the process is prepared for the next element.

The rotomolding process provides several advantages over other plastic-type production strategies. First, it permits intricate styles and factors to become manufactured effortlessly. The mold may be designed with complex details and complex pieces, which can be tough and dear to accomplish with some other approaches. Second, the rotomolding procedure produces a consistent walls size over the overall element. This will make the constituents stronger plus more durable than should they were actually made making use of other methods. Finally, the rotomolding procedure demands far less secondary finishing work than other approaches. The parts can be taken off from your mold and applied immediately, reducing lost time as well as labour.

Rotomolding has a variety of apps in various businesses. Within the automotive sector, rotomolded elements can be used for gasoline tanks, dashboards, and motor includes. In the health care industry, rotomolded parts can be used for health-related-level gear such as surgery trays and individual assist techniques. From the telecommunications sector, rotomolded factors can be used for real estate backyard equipment, for example signal amplifiers and transmitters.

In short:

Rotomolding is definitely an progressive and efficient plastic-type production method that gives quite a few benefits of those that utilize it. It really is a inexpensive way of manufacturing that produces sophisticated parts with constant quality and consistency. It includes a variety of software in several market sectors, and it is becoming more and more common as manufacturers seek trustworthy and sturdy developing methods. If you are looking for the greater method to generate powerful and dependable plastic material components, the rotomolding process could possibly be the respond to.